Electrical Works

In addition to our specialist heritage projects, CES also handles all scales of electrical work – from a single socket change to complete electrical overhauls.

CES has a heritage of training apprentices to work competently within historic sites, places of worship and other architecturally sensitive buildings. This experience in those environments sets CES apart when working in schools or public buildings too (safety, compliance, etc.).

As a family business, CES typically works on only two or three large projects at a time, ensuring that the client receives a personal service that is efficient and dedicated to their needs.

Please explore the tabs below to find out more information about the electrical services that we offer.

CES is able to offer electrical consultancy/design assistance to architects, interior designers or any other party involved.

We offer the following services:

- - Individual Aspect Design (Examples: individual room design within an overall project)

- - Electrical Surveys

- - Load Calculations

- - 2D Wiring Layout Drawings

- - Product Selection

- - Technical Reports

The submitted documents and associated fees will be tailored to the requirements of the client.

The electrical quotation and tendering process involves several key steps where contractors submit detailed proposals to clients for electrical projects. It starts with reviewing project specifications, conducting site surveys, and assessing material and labour costs. A comprehensive and competitive quote is then developed, outlining the scope of work, timeline, and pricing. Once submitted, the client reviews tenders, often selecting the best value proposal based on cost, quality, and expertise. CES LLP is well-equipped to carry out this process, offering clients a transparent, efficient, and professional approach. With years of experience in the industry, CES ensures that all quotations and tenders are accurate, competitive, and tailored to meet specific project requirements. Its commitment to quality service, detailed documentation, and prompt communication makes it a trusted partner for both small and large-scale electrical projects, ensuring successful outcomes for all parties involved.

CES provides maintenance and small electrical works to support ecclesiastical, heritage, and educational buildings. Our small works services range from installing new wiring for electrical items such as heaters, extraction fans, and switches to adding sockets for modern requirements like donation stations. Our maintenance services cover everything from routine lamp changes to high-level repairs and general electrical upkeep. With our experience in working with sensitive and historic spaces, we ensure all work is carried out to the highest standards while respecting the integrity of the building.

CES has a team exclusively dedicated to the routine maintenance of clients' facilities.

Types of Routine Maintenance carried out:

- - Improvement works

- - Repair works

- - General electrical maintenance

- - Internal lighting

- - External lighting

CES offers annual contracts and regular interval maintenance contracts as well as maintenance when deemed necessary by the Client or inspection reports.

Electrical Installation Condition Reporting (EICR) is an essential inspection of an electrical system to assess its safety and functionality. (This process is normally required by the diocese and the church insurance company to be carried out every 5-years). The report identifies potential hazards, deterioration, or non-compliance with current regulations, ensuring the installation is safe for continued use. EICR is carried out by a qualified electrician and involves checking wiring, circuit breakers, earthing, and other critical components.

Periodic EICR is crucial because electrical systems degrade over time due to factors such as wear, corrosion, or outdated components. Conducting regular inspections helps prevent accidents like electrical fires, shocks, or system failures. It also identifies areas requiring immediate attention, reducing the risk of costly repairs.

Before installing major systems like heating, small power or lighting, an EICR ensures the existing electrical infrastructure is safe and capable of handling additional load. This proactive approach helps maintain safety standards, avoid potential hazards, and ensures compliance with regulations.

What is tested?

-

Distribution Boards and Circuits:

- Every accessible distribution board and associated circuits are checked and tested.

- Includes areas like boiler rooms, crypts, towers, and roof voids, if applicable.

-

Inspection Scope:

- Schedules of Test Results: A detailed record for each circuit and distribution board.

-

Schedules of Inspections: Describes observations coded as:

- Code 1 (C1): Dangerous, requiring immediate attention.

- Code 2 (C2): Potentially dangerous, needing action soon.

- Code 3 (C3): Recommendations to improve compliance with BS 7671 standards.

- Costing for Observations: Provides an estimate to rectify non-compliances.

- Electrical System Schematic: Diagram outlining the layout of the system.

- Testing Limitations:

- Insulation Resistance Testing:

- Conducted between live and earth conductors to assess wiring integrity.

- Testing between live and neutral and neutral and earth is omitted to avoid disconnecting all electrical equipment on the circuit.

- Fixture and Accessory Testing:

- 20% of sockets, light fittings, and similar accessories on each circuit are opened and inspected to evaluate the quality of installation and materials.

- Sub-Mains Cables:

- 100% of these are tested.

- Insulation Resistance Testing:

- General Standards and Compliance:

- All work aligns with:

- BS Codes of Practice.

- Electrical Working Regulations.

- Local Authority Requirements.

- Health and Safety at Work Act. Standards by NIC EIC and UKAS EN45011.

- All work aligns with:

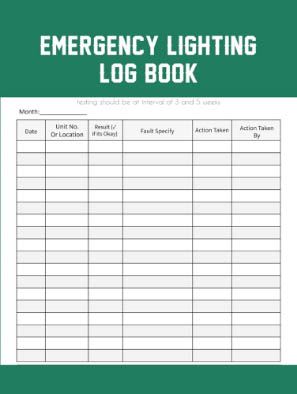

Periodic emergency lighting testing is a crucial practice to ensure that emergency lighting systems are fully operational when needed. These systems are designed to provide illumination during power outages or other emergencies, helping people navigate safely in dark or hazardous conditions. Testing involves regular checks of the lights, batteries, and other components to verify their functionality and compliance with safety regulations.

The importance of periodic testing lies in its ability to prevent system failures during critical moments. Emergency lights are essential for guiding occupants to exits, especially in buildings with complex layouts or where evacuation may be difficult. Failure to maintain these systems can lead to accidents, injuries, or even fatalities in the event of an emergency.

Regular testing helps identify any faults or issues, such as dead batteries, faulty wiring, or malfunctioning bulbs, allowing for timely repairs. This ensures that the emergency lighting will function as intended and protect the safety of building occupants.

What is tested:

Daily: - Client Responsibility

Visually check that all maintained lamps are operating and that all system healthy indicators on Central Power Supply Systems (Central Battery Systems) are illuminated.

Verify any system fault recorded is given urgent attention, and record all corrective actions in the log book.

Monthly:- Client Responsibility

Check all luminaires and other emergency lighting equipment is in a good condition, all lamps and light controllers are clean, undamaged and not blackened.

Briefly test all emergency lighting equipment by simulating a failure of the normal lighting supply. Check that all equipment functions correctly.

Check that once the mains supply is restored, all supply healthy indicators are again illuminated.

Yearly: - Competent person / Company Responsibility

A full system test should be conducted by a competent service engineer including a full three hour rated duration test of the system. Compliance of the installation and system with the requirements of BS EN and BS standards should be considered and documented.

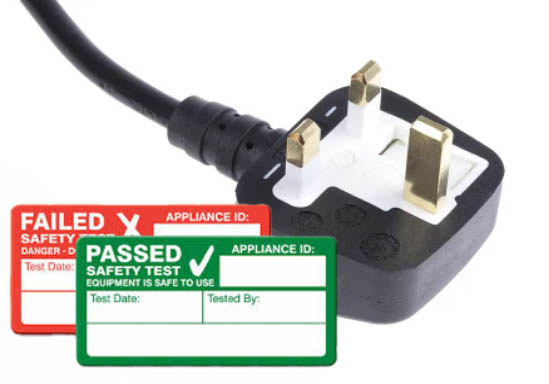

Portable Appliance Testing (PAT) is a process used to ensure the safety of portable electrical appliances and equipment in the workplace or at home.

It involves checking appliances for potential faults that could lead to electric shocks, fires, or other hazards. The process typically includes visual inspections, testing the integrity of the power cord, plug, and insulation, and ensuring that the appliance meets safety standards.

PAT is essential because it helps to identify faulty appliances that may pose risks to users and prevents accidents. Regular testing ensures that equipment remains in safe working order, particularly in environments where many people use electrical items, such as offices, schools, and industrial settings.

By conducting PAT, employers and property owners fulfil their legal obligations to maintain a safe environment and reduce the likelihood of costly injuries or damages. Overall, PAT contributes to workplace safety and compliance with regulations, promoting a safer and more reliable use of electrical equipment.

What is tested:

The testing process for portable appliances involves the following key steps:

Initial Inspection: Visually check for damage, ensure proper labelling, and inspect the plug and cable.

Electrical Testing: Test for earth continuity, insulation resistance, correct polarity, and leakage current to ensure electrical safety.

Functional Testing: Check if the appliance operates correctly, including controls, performance, and temperature regulation.

Mechanical Testing: Apply stress and impact resistance tests to ensure durability and the integrity of the appliance’s housing.

Safety Features Check: Verify overload protection, heat dissipation, and other safety features function properly.

Final Inspection: Confirm compliance with relevant safety standards and document the test results.

Marking and Labelling: Label passed appliances with a "Tested" mark and specify testing details.

Periodic Retesting: Appliances should be periodically retested to maintain safety, especially for those in regular use.

Contact Us

Have a question or a project in mind? Get in touch — we’re here to help and happy to discuss your requirements.